Large Automatic chicken nugget Processing line can automatically finish the procedure of forming, battering, flouring (predusting), tempura battering processing. This line shares the reputation of high automatization, easy operation, very simple cleaning design. And it is designed in conformity with the standard of HACCP. It can combine with frying machine and IQF and packing machine to complete chicken nugget production.

This line can process diversified materials:

Meat : Poultry, beef ,mutton, pork etc.

It regularly becomes the most ideal choice for the large scale factory.

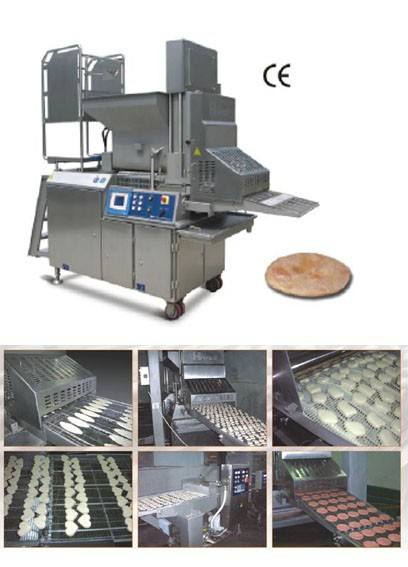

Automatic Multi Forming machine AMF600-IV

Automatic Multi Forming machine AMF600-IV can automatically perform various procedures such as meat filling, forming and outputting, and combine a fully automatic prepared food line when connecting with the batter, preduster, fryer, cooker, instant freezer and packing machine. It adopts the method of four-screw feeding system, greatly reduces the cutting of the material, and has better features of high production capacity and stable quality. It can be used to produce hamburger patty and chicken nuggets etc.

Technical parameter

Power | 15.12KW |

Production capacity | About 500-1000kg/hour |

Stroke Times | 15-60 times/minute |

The thickness of product | 6-40mm |

Weight Error | Less than or equal 1% |

The maximum diameter | 150mm( for round burger ) |

Filling pressure | 3-15Mpa adjustable |

Overall dimension | 3170×1176×2636mm |

2. Battering machine SJJ600-IV

Battering machine SJJ600-IV can offer a even coating of the chicken (poultry), beef, meat, seafood etc with a two-layer batter curtain on the top and a batter under-bath. It is suitable for the processing procedure before breading and predusting.

Technical parameter

Speed of the belt | 1.5-15m/min adjustable |

Input height | 1050mm |

Output height | 800-1100mm |

Width of the belt | 400mm and 600mm available |

Power | 2.52KW |

Overall dimension | 2400×935×1700mm |

3. Flouring Machine (Preduster) SFJ600-IV

The preduster applies a mixture of flour and breading accurately and evenly when the products pass the belt, to meet the requirement of the next processing step. Using air flow system to collect leak flour, leak flour is reused. And it can be combined to the battering machine and breading machine to make different production lines for the different processing: predusting-battering-predusting, battering-predusting, battering-predusting-breading and etc.

Technical parameter

Speed of the belt | 1.5-15m/min |

Feed height | 980-1070mm |

Output height | 1000-1120mm |

Width of the belt | 600mm (400mm available) |

The electricity | 380V/50Hz |

Power | 2.95KW |

Overall dimension | 2655×1055×2220mm |

4. Tempura Battering Machine (dipper) NJJ600-IV

Tempura battering machine (dipper) NJJ600-IV realized the batter coating by dipping the products into the batter bath. It is widely used in the Tempura products, meat, poultry, seafood and vegetable.

The space between the upper and lower belt can be adjusted, which gives a wide range of variety products.

THE PRODUCT HAS ADVANTAGE AS FOLLOW:

1. Powerful blower and vibrator can remove the excess batter.

2. Easy and reliable operation and adjustment.

3. Using SIEMENS electric apparatus, and reliable protection device.

4. Dismantle design, easy to completely clean, meet the HACCP standard and got the CE authorization.

5. Independent output belt available to your choice.

Technical parameter

Speed of the belt | 1.5-15m/min (frequency conversion) |

Feed height | 980-1120mm |

Output height | 800-1100mm |

Width of the belt | 400mm and 600mm available |

The electricity | 380V/50Hz |

Power | 1.77KW |

Overall dimension | 3100×920×1600mm |